Woven PTFE Spherical Bearings

INTRODUCTION

Cosmec TeXLon™ Spherical Bearings are a range of structural bearings allowing large angular rotation, with a minimum of resistance, about any horizontal axis.

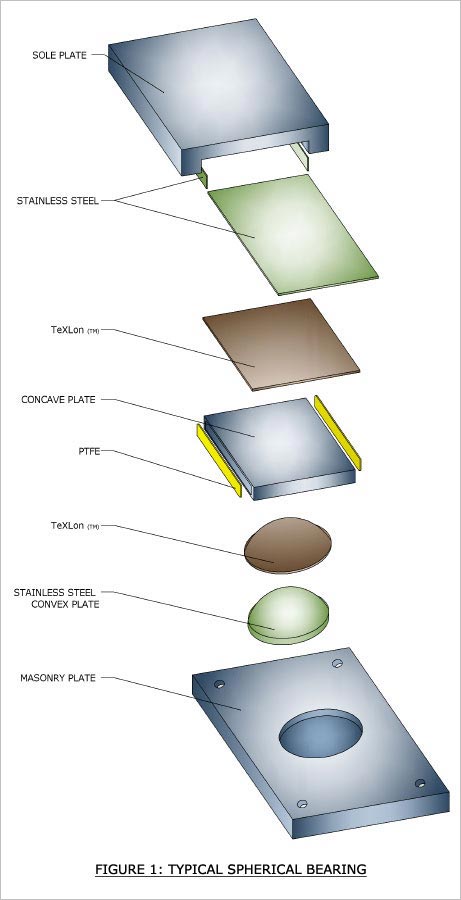

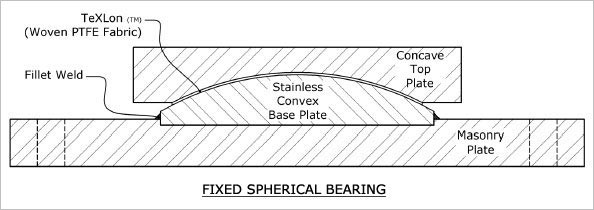

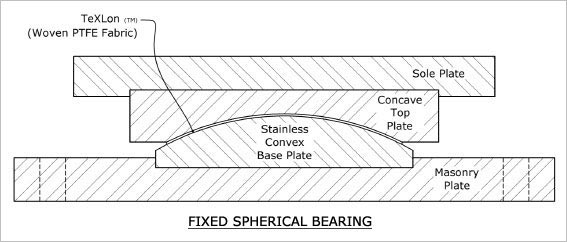

Comprised of a convex base with a mating concave element, the basic bearing offers rotation of ±0.04 radians (2 1/4°) by sliding at the curved interface of the two plates. Greater rotations are also available. This is a Fixed-Point Rotational Bearing.

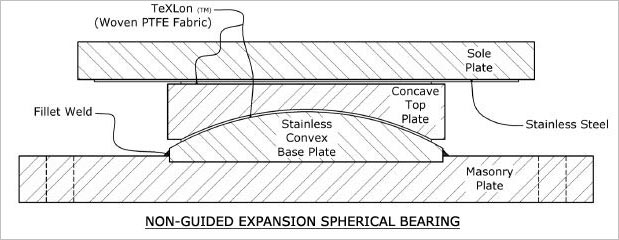

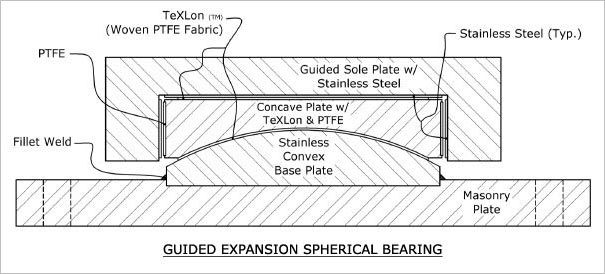

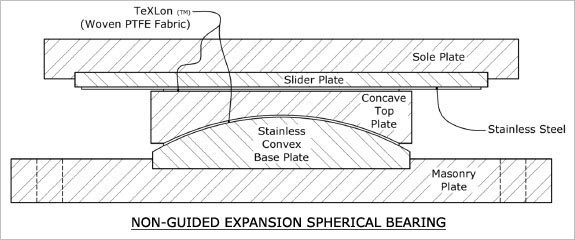

Provisions can be made for horizontal movement by the addition of an upper plate with a horizontal slip plane between it and the concave rotational element. Figure 1 illustrates the complete system.

Provisions can be made for horizontal movement by the addition of an upper plate with a horizontal slip plane between it and the concave rotational element. Figure 1 illustrates the complete system.

Practical bearings of this type can be designed for most any combination of loads, structural movements and rotations found in today’s bridges. They have the following performance advantages:

a.) High rotation capacity: This is easily obtained in a Spherical Bearing by modest dimensional differences between mating parts. By contrast, bearings with elastomeric rotation elements must be made progressively thicker for increasing rotation, which in turn demands larger shear devices or bigger pots in pot bearings. If the elastomer is not confined, the added thickness means greater vertical deflection.

b.) Minimal rotation resistance: In a Spherical Bearing this is assured by low friction between the mating parts. Resistance is lower than any current bearing design for rotations over 0.02 radians. This is most important when assessing bending moments imposed on the substructure.

c.) Constant rotational resistance: In Cosmec Spherical Bearings, rotational resistance is constant because the frictional force is constant at all degrees of rotation; thus eccentricity of loading is one low figure even in extreme rotations. All other bearing designs have rising eccentricities that cause commensurate increases in bending moments; increases that can be extreme in Elastomeric Disc or Pad Bearings.

d.) Rotational preset: This is easy with Spherical Bearings; a particular advantage for some erection procedures on cable-stayed, segmental or cantilever structures. Rotational preset is virtually impossible with bearings having elastomeric rotational elements.

e.) Negligible vertical deflection: Under load, Spherical Bearings offer no deflection related problems with expansion joints, rails, service ducts or other inter-structure details.

STANDARD BEARINGS

The bearings detailed in the following examples represent a typical range of economical units. Included are Fixed, Non-Guided Expansion and Guided Expansion Bearing Units. These units are the best for low height and are usually the lowest in cost.

Where replaceability is an issue, the following Spherical Bearing units with removable base plates are recommended:

DESIGN ALTERNATIVES

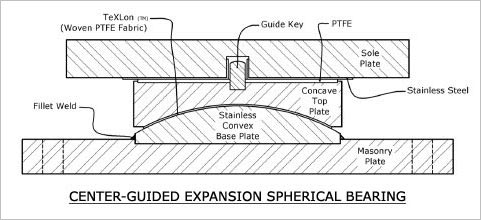

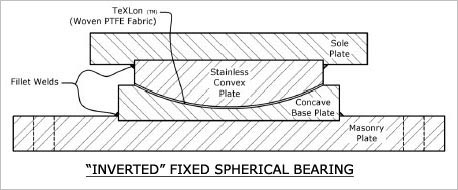

The bearings detailed in the following examples are alternative bearing configurations that are produced by Cosmec that may be used for specialized applications or special requirements.

|

CENTER-GUIDED EXPANSION SPHERICAL BEARING: May be used when a lower profile is required. Is used best when horizontal loads are relatively small (less than 20% of vertical Load). Many different low-coefficient of friction surfaces are possible and different configurations are possible for the guide key. |

|

“INVERTED” FIXED SPHERICAL BEARING: Can be used when the height of the bearing must be kept as low as possible – such as for rehabilitation projects. |

|

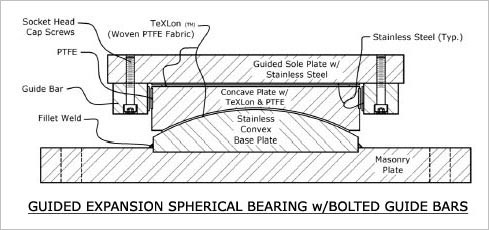

GUIDED EXPANSION SPHERICAL BEARING WITH BOLTED GUIDE BARS: These can be used when removable guide bars are desired. |

|

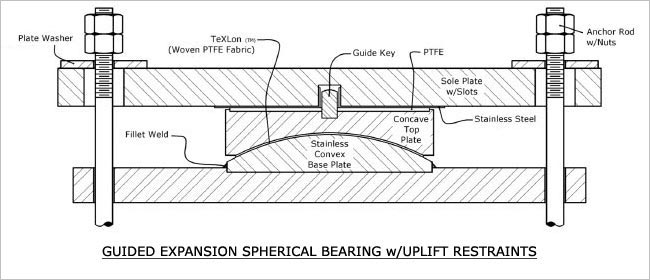

SPHERICAL BEARINGS WITH UPLIFT RESTRAINTS: Cosmec can design Spherical Bearings with uplift restraints when some uplift is anticipated. One possible configuration is shown, however many differing configurations are possible. |

We can customize bearings as required. Please contact our Engineering Staff for suggestions.

DESIGN and MATERIALS

PTFE is the now-familiar, low-friction material used in the slip plane in many designs of structural bearings. This material possesses the attractive feature of a reduced coefficient of friction with increasing loads. But in sheet form, the tensile strength of 2800 psi limits the loading allowed. Bearings designed with this material therefore must achieve a compromise between high unit loading and cold flow. Fillers can reduce cold flow, but they increase cost and the coefficient of friction; both of which are undesirable.

“TeXLon™” is the trade name for Cosmec’s 100% PTFE matting. PTFE fiber has a tensile strength nearly 16 times that of pure PTFE sheet material and therefore TeXLon™ can sustain far greater working loads without cold flow. The higher strength is inherent in the spun yarn and does not depend on any filler material. TeXLon™ is pure PTFE, not a woven composite.

TeXLon™ has a minimum thickness of 0.05” after compression and is mechanically interlocked to a rigid substrate. The interlock pattern is equally distributed over no less than 25% of the bearing area and is of sufficient profile and strength to withstand 10% to 20% of the vertical unit load applied horizontally without consideration of the effect of supplemental adhesive. The PTFE resin from which the fabric material is produced, is virgin material that meets the requirements of ASTM D4894.

Stainless steel is 16 ga. minimum thickness conforming to ASTM A240 Type 304 or Type 316 with a maximum surface finish of 20 RMS. Major carbon steel components are ASTM A709 Grade 50 (AASHTO M270 Grade 50) steel, and ASTM A709 Grade 50W (AASHTO M270 Grade 50W) weathering steel or ASTM A709 Grade 36 (M270 Grade 36) will be considered on demand.

All materials for all US bearings will be certified domestic material manufactured and fabricated in the USA in accordance with the “buy American” requirements for all Federally funded work.

Testing can be undertaken to fulfill all requirements of the AASHTO Specifications and any other specialized testing as may be required. Most testing can be performed in our own testing facilities.

Coating on the bearings can be the latest high performance paints, including high-solids zinc primers, or the bearing assemblies can be metallized (zinc or zinc/aluminum thermal spray coatings). Galvanizing of the carbon steel components can be considered on demand. Coating recommendations can be made to insure a long-lasting product no matter what the environment.

STRUCTURAL DESIGN CONSIDERATIONS

Expansion Bearings should be mounted with the flat stainless steel sliding surface facing down so as to avoid the accumulation of dirt and debris that can affect the sliding performance of the bearing over time.

Fixed Bearings may be mounted any face up.

Slide plate offsets can be provided when specified.

Spherical Bearings are not designed to take bending moments. They must be provided with even, flat seats. High-strength grout or rubber or fabric pads are recommended. Leveling blocks or bolts must be removed after erection. Shims, when used, must cover the entire bearing area.

Formwork may be constructed around a bearing for poured-in-place concrete structures. Seal between bearing and formwork to prevent contamination by laitance or concrete. Offsets should be established in advance.

Spherical Bearings can accommodate many anchoring systems. While we do not cover those systems here as they are considered to be part of the structural engineering design, suggestions for best compatibility with our bearings will be offered on request.

INSTALLATION

Cosmec Spherical Bearings are manufactured to close tolerances in a controlled environment. Care must be taken in the handling and installation to ensure they start their service life in a clean undamaged condition. They should be stored under cover and off the ground. Retainer clips or strapping are used to hold bearing parts together for shipping and erection; they must be removed to allow the bearing to function, but not before final positioning and only at the Engineer’s direction. Rotational or slide plate offsets should be set in the shop, but they may be re-set on site.

Bearings should not be disassembled on site without direct supervision by qualified personnel. We will not be responsible for the subsequent non-performance of a bearing if disassembly occurs without our supervision and written approval. In case of inadvertent disassembly, call us immediately.

Lift bearings by their bases only. Do not rely on transportation straps or brackets to carry the bearing’s weight.

Do not specify paint or coatings on the PTFE/stainless sliding surfaces or in the interior of the Spherical Bearing.

Specialized lifting “lugs” or setting fixtures can be designed and fabricated by Cosmec to meet special needs for the erection, installation and/or setting of the bearings. These items will be considered on demand. Please contact our Engineering staff with any such requirements before the final design of the bearings.