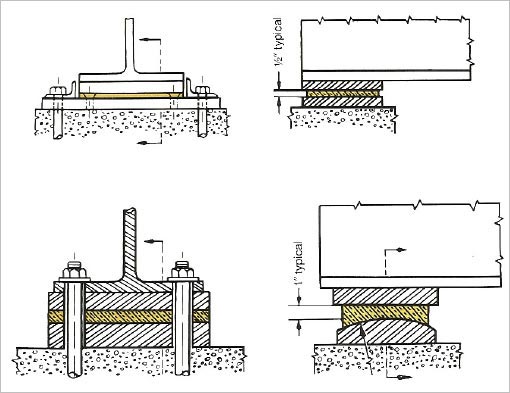

A common application is uniplanar expansion and contraction. In this design, only one face, usually the upper, of the COSMEC XL expansion plate is lubricated. It is commonly "nested" in or fastened to the base or masonry plate. A sole plate fastened to the beam or superstructure slides on the lubricated surface.

Where unidirectional deflection or rotation of a beam must be provided for, as well as expansion and contraction, either of the above or below designs will provide a solution.

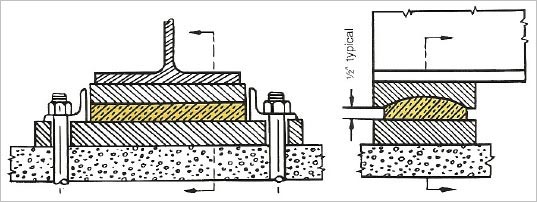

The two self-lubricating bearing surfaces allow expansion and contraction on the flat face, and deflection of the beam is permitted on the radial face-on fixed bearings; only the radial face is lubricated. These designs, which allow for the rotation of the beam, ensure uniform distribution of loading on both bearing surfaces.

Today's bridge and structural designs are becoming increasingly complex with the necessary skews and wider spans. Also spans are being made longer with greater load carrying capacity. These requirements create unique design problems in the development of bearings to support these increased loads and transmit the loads uniformly through to the foundation with minimum overturning moment.

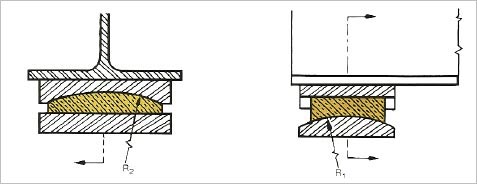

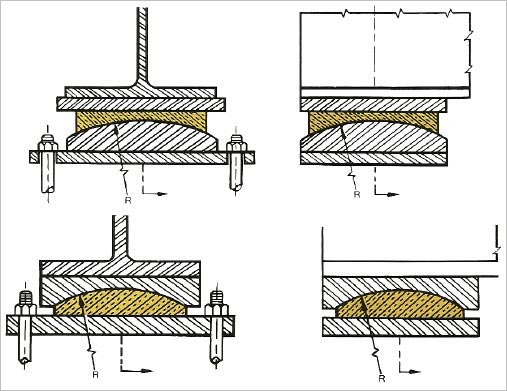

The designs shown on this page offer complete self-alignment as well as providing for expansion and contraction in all directions.

The "Bi-radial" expansion plate is comprised of two self-lubricated circumferentially radial surfaces. They may be either concave or convex. However, the design shown with the upper radius convex and the lower radius concave is recommended. Both mate with their respective identical radii in the sole and base plates. The upper radius need not be the same as the lower radius.

Longitudinal expansion and transverse rotation are permitted on the upper convex radial surface. Longitudinal rotation and transverse expansion are permitted on the lower concave radial surface. The radii being at 90 degrees to each other allows rotation in any direction and complete self-alignment. Expansion and contraction take place along the radial axis of each surface.

The "Unisphere™" expansion plate also consists of two self-lubricated surfaces. One is flat, permitting expansion and contraction in all directions. The other is a spherical surface which permits deflection or rotation in all directions with this self-aligning feature. The spherical surface can be either concave or convex. The bearing may be either circular or rectangular.

The most common and universally accepted design of bushing is the one-piece or sleeve-type bushing. This design lends itself to the majority of all bushing applications. Other designs are adaptations of the one-piece design to meet particular conditions that require variations.

One-piece bushings are designed to meet the needs of general-purpose applications as well as heavy-duty applications by the selection of the proper supporting bearing material and/or by the selection of the internally lubricated design.

One-piece bushings are normally designed for rotary motion and will customarily be supplied for this type of service unless the conditions of the application warrant a different lubricating pattern.

Two-piece bushings are used where a two-piece housing or the requirement of installation ease necessitates quick assembly and disassembly of a unit.

Two-piece bushings are manufactured by temporarily bonding the two halves of the bushing as a one-piece unit before machining to the final dimensions. After machining, the halves are match-marked as a pair before separating. The match-marking facilitates mating at assembly.

Two-piece bushings are not necessarily two perfect half bushings, as the matchline may not be coaxial. Perfect half bushings are not economically practical and should only be specified where the center or split line is extremely critical to the application.

Flanged bushings combine the features of a sleeve bushing and a washer into an integral unit. The flange may be located on one or both ends and is usually the same thickness as the wall of the bushing.

Extreme differences between the outside diameter of the bushing and the outside diameter of the flange may dictate the use of a separate bushing and washer for reasons of economy.

The flange may be lubricated to take end thrust or plain to act as a spacer or holding flange.

The flange may have through holes or countersunk holes for bolting to the housing.

Thrust washers are usually used alone or in conjunction with a sleeve bushing to take rotational end thrust that might otherwise be transmitted to the end of the bushing or the side of the housing.

Thrust washers may be lubricated on one or both faces as the conditions require. Depending on size and configuration, it is often more economical to use a thrust washer in conjunction with a sleeve bushing rather than a flanged bushing.